Surgery to repair one of the most common causes of lower back pain will be shorter, have less risk of complications, and result in faster patient recovery times, thanks to a novel device developed at The University of Toledo.

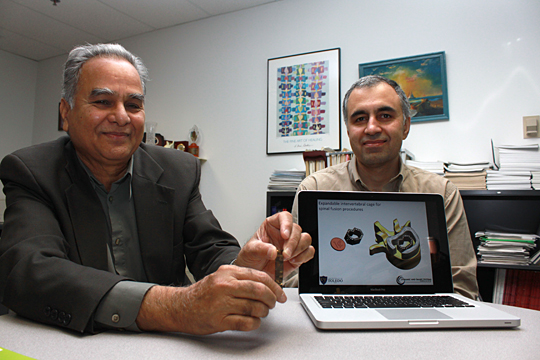

Dr. Vijay Goel held the intervertebral device that he and Dr. Mohammad Elahinia designed to make spine surgery less invasive and recovery time for patients much shorter.

One of the most common causes of lower back pain in people age 45 to 65 is the compression of an intervertebral disc that creates pressure on nerves extending from the spinal cord. While current spinal fusion procedures — expanding the spacing between vertebrae by surgically removing an improperly functioning disc and replacing it with an implanted device called a cage — often succeed in the decompression of nerves and relief from debilitating pain, the operation is invasive and has a high risk of injury.

Dr. Mohammad Elahinia, lead researcher and UT associate professor of mechanical, industrial and manufacturing engineering, said the new device will provide surgeons with an alternative to traditional spinal implant cages.

“Our cage is different because it is comprised of a chain of linked segments connected by hinges, and it is inserted vertically or horizontally into the inter-vertebral cavity one link at a time,” said Elahinia, who also serves as director of the Third Frontier Project Nitinol Commercialization Accelerator to advance the development of products made from the alloy of nickel and titanium. “This allows for an incision as small as 6 millimeters wide and 10 to 20 millimeters high.”

Watch an animation of the cage insertion:

Dr. Vijay Goel, UT professor and chair of orthopedic bioengineering, said the unique design of the cage is a clear improvement over current devices because it allows for easier insertion and faster, safer recovery for patients.

“Because of the smaller, single incision, this device minimizes the risks of spinal fluid leak and penetration of the dura, the outer layer of the spinal cord,” said Goel, who in addition to working with Elahinia serves as co-director of the Engineering Center for Orthopedic Research Excellence (E-CORE) in UT’s colleges of Engineering and Medicine and Life Sciences. “It eliminates the need to remove all or most of the spinal and vertebral structures to operate and, therefore, it increases the overall structural stability and reduces risks.”

In the case of spinal implant surgery, the cage becomes the stabilizing element within the spine to support fusion.

Goel, Elahinia and Cory Chapman, a UT graduate research assistant in the Department of Mechanical, Industrial and Manufacturing Engineering, constructed the cage out of a material with proven efficacy, biocompatibility, cost-effectiveness and strength that more closely resembles bone than stainless steel.

Further, Elahinia said, the material readily accepts applications of bioconductive material coatings to aid in bone growth and fusion. The cage is self-actuating, using shape memory alloys to take and hold any desired form.

Additionally, the open design of the device allows the surgeon to move and adjust the device to allow proper placement and insertion of various types of bone graft material.

Two spine surgeons, Dr. Ashok Biyani, associate professor of orthopedic surgery who recently joined ProMedica, and Dr. Anand Agarwal, a spine surgeon and research professor at E-CORE, have helped the team throughout the design and evaluation process.